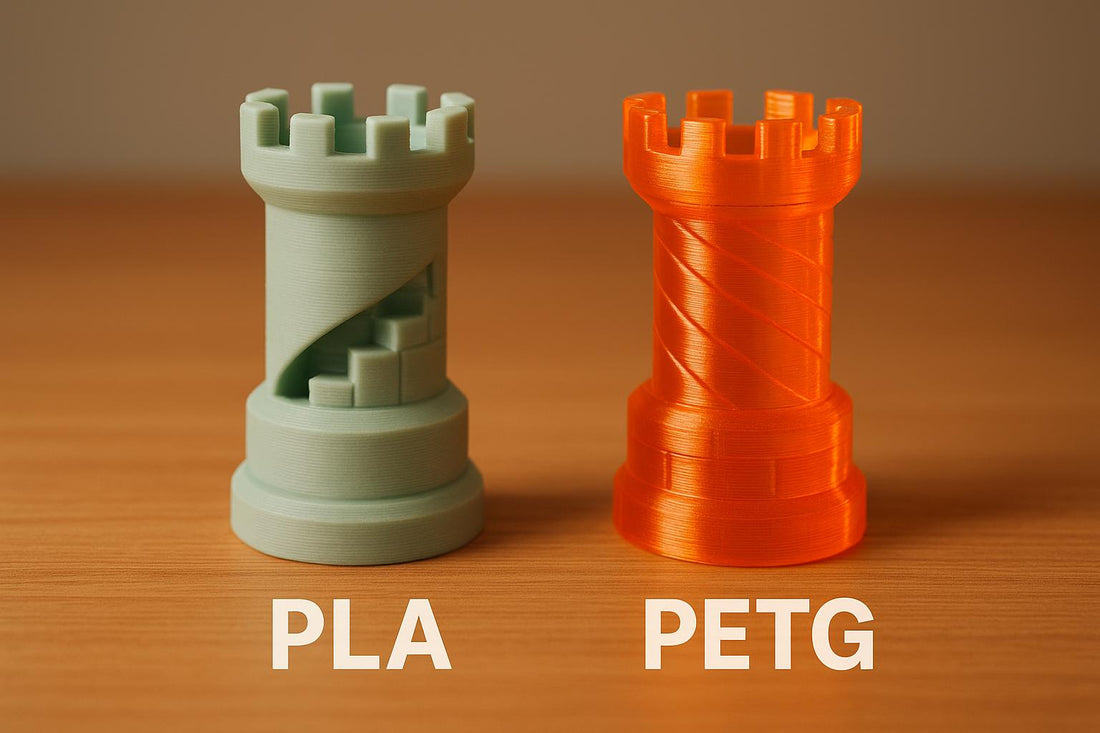

PLA vs PETG: Which 3D Printing Material is Better?

When deciding between PLA and PETG for 3D printing, it all comes down to your project’s needs. PLA is ideal for decorative items, prototypes, and detailed miniatures thanks to its ease of use, low printing temperature, and smooth finish. PETG, however, is better for functional parts and durable components due to its higher strength, impact resistance, and flexibility.

Key Differences:

- PLA: Prints easily, lower cost, no heated bed required, biodegradable, but less durable and softens at lower temperatures.

- PETG: Tougher, more flexible, higher temperature resistance, but trickier to print, requires a heated bed, and has a stronger odor.

Quick Comparison:

| Feature | PLA | PETG |

|---|---|---|

| Print Temp | 200–220°C (392–428°F) | 230–250°C (446–482°F) |

| Bed Temp | Optional (~60°C/140°F) | Required (79–85°C/175–185°F) |

| Strength | Moderate | High |

| Flexibility | Rigid, brittle | Semi-flexible |

| Durability | Low | High |

| UV Resistance | Poor | Good |

| Cost | Lower | Higher |

Choose PLA for simplicity and aesthetics, and PETG for strength and durability. Your printer setup and project goals should guide your decision.

PLA vs PETG: Which 3D Printing Filament is Best for Your Project?

How Easy Each Material Is to Print

When it comes to 3D printing, the ease of working with PLA and PETG can vary quite a bit. Factors like your printer setup and experience level will heavily influence which material feels easier to handle.

Printing Difficulty Levels

PLA is often the go-to material for beginners because it’s straightforward to work with. It prints at temperatures between 200–220°C (392–428°F) and doesn’t necessarily need a heated bed, although setting the bed to around 60°C (140°F) can improve first-layer adhesion. PLA flows smoothly, resists warping, and tolerates slight temperature fluctuations, making it a forgiving option.

PETG, on the other hand, demands more precise settings. It prints at higher temperatures, typically 230–250°C (446–482°F), and requires a heated bed set to 79–85°C (175–185°F). PETG’s sensitivity to temperature means you’ll need to slow down the printing speed to around 30–50 mm/s to avoid issues like stringing, compared to PLA’s faster and easier 60–80 mm/s range.

Warping is another area where the two materials differ. PLA cools with minimal shrinkage, so it’s usually warp-free on most surfaces. PETG, however, can shrink a bit more as it cools, which might cause corners to lift on larger prints if the bed adhesion or temperature isn’t just right.

When it comes to bed adhesion, PLA sticks well to a variety of surfaces, including glass, PEI sheets, or even painter’s tape. PETG can be trickier, often requiring specific surfaces or adhesion aids. Plus, PETG bonds so strongly that it might damage your print bed during removal if you’re not careful.

Fumes and Ventilation Needs

Environmental factors are also worth considering. PLA is virtually odorless, making it a great choice for printing in enclosed spaces. PETG, however, releases a faintly sweet chemical odor, so proper ventilation is a must when using it.

3D Printer Compatibility

PLA is compatible with almost every 3D printer on the market. Its low printing temperature means even basic printers without a heated bed or advanced hotends can deliver excellent results.

PETG requires a bit more from your printer. You’ll need a hotend capable of reaching 230–250°C (446–482°F) consistently. Budget printers with PTFE-lined hotends might struggle at these temperatures, and skipping a heated bed can lead to poor adhesion and failed prints - especially for larger objects.

Another consideration is nozzle wear. PLA is gentle on standard brass nozzles, showing minimal wear even after extensive use. PETG, being slightly more abrasive, can wear down nozzles faster, though this typically becomes an issue only after prolonged use. Also, while PLA releases easily from most print surfaces once cooled, PETG’s strong adhesion can potentially damage delicate bed surfaces if you’re not careful during removal.

Strength and Performance Comparison

Choosing between PLA and PETG often comes down to understanding how they perform under stress. Both materials offer distinct advantages, but their physical properties make them suitable for different types of projects.

Material Properties Comparison Table

| Property | PLA | PETG |

|---|---|---|

| Tensile Strength | 37-41 MPa (5,365-5,945 psi) | 50-55 MPa (7,252-7,977 psi) |

| Impact Resistance | Low to moderate | High |

| Flexibility | Rigid, brittle when bent | Semi-flexible, bends without fracturing |

| Layer Adhesion | Good | Excellent |

| Temperature Resistance | 140-158°F (60-70°C) | 176-194°F (80-90°C) |

| UV Resistance | Poor, degrades over time | Good, maintains properties |

| Chemical Resistance | Limited | Excellent against most chemicals |

When it comes to tensile strength, PETG has a clear edge, offering about 35% more strength than PLA. This makes PETG better at withstanding pulling forces before breaking. However, the real standout feature is how PETG handles impact and bending forces - it’s much more forgiving than PLA, which tends to crack under similar conditions.

Real-World Performance

The differences in material properties become even more apparent in practical applications. For example, PETG's flexibility makes it ideal for items like fidget toys. Designs such as the Flexi ArticuLotl or Crystal Dragon benefit from PETG’s ability to bend repeatedly without cracking, while PLA might fail at stress points after prolonged use.

For gaming accessories, the choice depends on the item's purpose. PLA is excellent for intricate, decorative pieces like the Vampiric Resistance Dice Tower, where sharp details and rigid structures are key. Its stiffness enhances the precision of fine textures and gothic designs. On the other hand, PETG is better suited for functional pieces that endure heavy handling, like dice towers used in weekly game nights. PETG’s higher impact resistance ensures it won’t shatter if dropped or knocked over.

Temperature resistance is another factor to consider. PLA softens at around 140°F (60°C), which means it can warp if left in a hot car or exposed to high temperatures. PETG, with its higher resistance (176–194°F or 80–90°C), retains its shape and strength even under fluctuating conditions.

Layer adhesion also plays a critical role, especially for functional parts. PETG’s superior bonding between layers ensures durability in moving parts, hinges, and threads, reducing the risk of delamination under stress. While PLA’s adhesion is good, it may not hold up as well in designs subjected to repeated flexing or twisting.

For everyday items like keychains - think Amanda the Panda or Myrtle the Turtle - the material choice directly affects durability. PLA keychains might develop cracks at stress points, such as where the keyring attaches, after months of use. PETG versions, while slightly trickier to print with fine details, handle the constant stress of bouncing keys much better.

UV exposure is another important consideration. PLA tends to degrade when exposed to sunlight, becoming brittle and potentially changing color over time. PETG, on the other hand, maintains its properties much longer, making it a better option for items that will be used outdoors or displayed near windows.

sbb-itb-c5cd7d3

Cost, Availability, and Environmental Impact

When choosing between PLA and PETG, two key factors often come into play: cost and environmental impact. Both materials are readily available across the US, but they differ in pricing and their ecological footprints.

Material Costs in US Dollars

If you're looking to save money, PLA is generally the more affordable option, making it ideal for large-scale projects or frequent printing. Specialty versions of PLA, like those with unique finishes, can cost more, but the price difference is usually more noticeable with PETG.

Another cost-saving aspect of PLA is its lighter weight, which can cut down on shipping expenses. Plus, PLA's ease of use during printing often results in fewer failed prints and less wasted material. PETG, on the other hand, requires higher printing temperatures and has a tendency to produce stringing, which can lead to increased material usage. That said, PETG’s durability makes it a worthwhile investment for functional items that need to withstand wear and tear over time.

Environmental Considerations

From an ecological perspective, PLA and PETG have distinct profiles. PLA is made from renewable resources like corn starch and sugarcane, and it’s biodegradable - but only under industrial composting conditions. It doesn’t break down easily in a typical home environment. PETG, being petroleum-based, isn’t biodegradable but has the advantage of being widely recyclable through curbside programs.

Energy consumption is another factor. PLA’s lower printing temperatures mean it uses less energy, which can add up to noticeable savings during frequent or large-scale printing projects.

Durability also plays a role in environmental impact. PETG is resistant to UV damage and impact, which means items made from it tend to last longer. This longevity can reduce the need for replacements, ultimately lowering material consumption over time. Choosing between the two materials often comes down to the intended use and local recycling options. PLA is a great choice for short-term or indoor projects, while PETG shines in applications requiring long-lasting, durable pieces.

Material Recommendations for 3rd Prints Products

When deciding between PLA and PETG for your 3rd Prints projects, it’s important to consider their unique properties. Each material shines in different scenarios, so let’s break down which one works best for specific types of prints.

Flexible and Moving Parts

For projects with moving parts or components that need to flex, PETG is your go-to material. It’s built to handle repeated stress, bending, and even impacts without breaking - a quality that’s crucial for articulated designs.

Take fidget toys like the Flexi ArticuLotl or Crystal Dragon, for instance. These creations feature segments that are manipulated repeatedly. PETG’s flexibility and impact resistance make it perfect for such applications. As Sara Wickstrom from Ultimaker puts it:

"PETG is stronger than PLA in terms of impact resistance, flexibility, temperature resistance, and overall durability."

Functional gaming accessories, like dice towers with hinged lids or adjustable mechanisms, also benefit from PETG’s properties. It absorbs impacts without cracking, unlike PLA, which struggles under stress. A user on Reddit, linux_assassin, explains:

"For anything that will flex, move, be under stress, be under load - PLA rapidly becomes a bad idea."

But what about projects where appearance takes precedence over function?

Display and Decorative Items

When aesthetics matter most, PLA takes center stage. This material is excellent for capturing fine details and achieving a smooth, polished finish, making it ideal for decorative pieces.

For example, the Skubbies Skeleton Keychain Figures showcase PLA’s ability to deliver intricate designs with minimal defects. Whether it’s ornamental desk items, display stands, or themed decorations for tabletop gaming, PLA’s wide variety of colors and finishes allows for stunning results. And since these items don’t endure mechanical stress, PLA’s limitations aren’t a concern.

However, for accessories that need to endure daily use, you’ll want something tougher.

Functional Accessories

For durable, everyday items, PETG outperforms PLA. It’s particularly well-suited for functional gaming accessories like dice towers with integrated can holders, such as the Vampiric Resistance Dice Tower or Cthulhu Dice Tower. These designs need to withstand repeated dice impacts and support the weight of a 12-ounce can. PETG’s strength and resistance to thermal stress ensure these accessories remain reliable over time, even when exposed to cold beverages.

PETG also excels in outdoor or high-temperature environments. Its resistance to heat and UV light prevents warping and degradation, making it a better choice for items exposed to the elements. As FormFutura explains:

"PETG stands tall in crafting components that dance between flexibility and shock resistance, creating a symphony of possibilities."

In short, PETG is the material for projects that demand durability and long-term performance, while PLA is best for designs focusing on aesthetic appeal and ease of printing.

Conclusion: Choosing the Right Material for Your Needs

When deciding between PLA and PETG, it’s all about what you’re making and how it’ll be used. Each material shines in different situations, so understanding their strengths can save you time, money, and frustration.

Go with PLA for simplicity, detail, and aesthetics. If you’re crafting decorative items or projects that require fine details and smooth finishes, PLA is your go-to. Its lower printing temperature and reduced warping make it user-friendly, especially for beginners or quick, straightforward prints. Plus, it doesn’t require fancy equipment to get great results.

Choose PETG for strength and durability. For items that will face regular handling, stress, or even outdoor exposure, PETG is the better option. Its impact resistance, flexibility, and tolerance for higher temperatures make it ideal for functional prints like tools, parts, or anything that needs to take a beating.

Don’t let price be your only guide. While PLA is typically $2–3 cheaper per kilogram, picking the wrong material can lead to wasted time and resources if prints fail or break. Always prioritize the demands of your project over minor cost differences.

For 3rd Prints products, the choice depends on the purpose of the item. PLA works beautifully for decorative keychains or display pieces, while PETG is the smarter choice for articulated fidget toys or gaming accessories that need to endure frequent use. If the item will bend, flex, or face regular handling, PETG’s added durability is worth the extra effort and cost.

Finally, consider your printer’s capabilities. Without an enclosed printer or proper ventilation, PLA might be your only viable option. But if your setup supports PETG, its resilience makes it a great pick for long-lasting, functional prints that can handle everyday wear and tear.

FAQs

What should I consider when deciding between PLA and PETG for my 3D printing project?

When deciding between PLA and PETG, it's important to weigh factors like durability, strength, and printing ease. PLA is an excellent choice for beginners - it prints effortlessly and works well for decorative items, prototypes, or custom gifts. On the flip side, PETG offers greater strength, flexibility, and heat resistance, making it a better option for functional parts or projects that need to withstand more stress.

Ask yourself: Is this project decorative or functional? Will it need to endure wear, tear, or high temperatures? If your project is straightforward and aesthetic, PLA is a solid pick. But if you’re tackling something more demanding, PETG is the way to go. Keep in mind, too, that PLA is generally easier to print, whereas PETG might require some adjustments to your printer settings for optimal results.

How do the environmental impacts of PLA and PETG compare, and how should this affect my choice?

PLA is often considered a greener choice compared to PETG. It’s derived from renewable resources like cornstarch and can break down under specific conditions, making it a more eco-conscious option for reducing long-term waste.

PETG, however, is made from oil-based polymers and isn’t biodegradable. That said, it can be recyclable in certain cases. While PLA leans toward sustainability, PETG stands out for its toughness and ability to withstand higher temperatures, which might make it a better fit for certain projects. Weigh your environmental goals alongside the practical needs of your project to decide which material works best.

What printer settings do I need to successfully print with PETG, and how are they different from PLA?

To achieve great results with PETG, your 3D printer needs a heated bed set between 165–194°F (75–90°C). This helps with proper adhesion and reduces the risk of warping. The extruder should operate at a temperature range of 446–482°F (230–250°C). For better surface quality and to cut down on stringing, using a part cooling fan is highly recommended.

When compared to PLA, PETG demands higher printing temperatures and relies on a heated bed for optimal performance. PLA, on the other hand, works well at lower bed and extruder temperatures. Another key difference is PETG’s low viscosity when melted, which makes dialing in the right retraction settings essential to prevent stringing. With these tweaks, PETG can deliver durable, high-quality prints for a variety of projects.